Tech Tip 5 Proper Piston Circlip Installation

Tech Tip #5

Proper Piston Circlip Installation

must be installed correctly. The simplest of a motors complex parts list is the spring wire circlip (red arrow). Installed correctly, in the piston pins groove, it never causes a problem. But, if incorrectly installed, severe cylinder damage can result.

must be installed correctly. The simplest of a motors complex parts list is the spring wire circlip (red arrow). Installed correctly, in the piston pins groove, it never causes a problem. But, if incorrectly installed, severe cylinder damage can result.

The proper way to install a circlip is to position one end of the clip in the groove with the other end at 30deg. past the cut out (blue arrow). Now, using a very narrow flatblade screwdriver, lever the clip inward and into its groove. You will hear it snap into place if done correctly.

inward and into its groove. You will hear it snap into place if done correctly.

Note: just in case you slip, cover the area under the piston’s skirt with a rag to prevent the clip from falling down inside the motor.

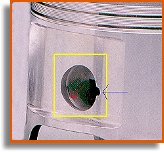

What happens if the clip isn’t completely in place? First, it pops out of it’s groove the first time the piston pin slides into it hard enough to dislodge it. The clip then proceeds to break into pieces, or fracture the piston or break up the rings causing damage outlined by the blue circle. Next the piston pin slides over farther until it is flush with the piston’s skirt as shown by the blue arrow. Then the pin begins to gouge a troth into the cylinder’s wall as outlined by the yellow circle essentially ruining the cylinder and requiring resleeving of the cylinder.

Remember NEVER reuse a circlip and listen for the snap as the clip expands into its groove AND verify it visually on BOTH sides!